Have you ever wondered why conveyor belt prices vary so significantly? Is it the material, the design, or the application that causes these differences? For businesses, choosing the right conveyor belt at the right price can make all the difference in operational efficiency.

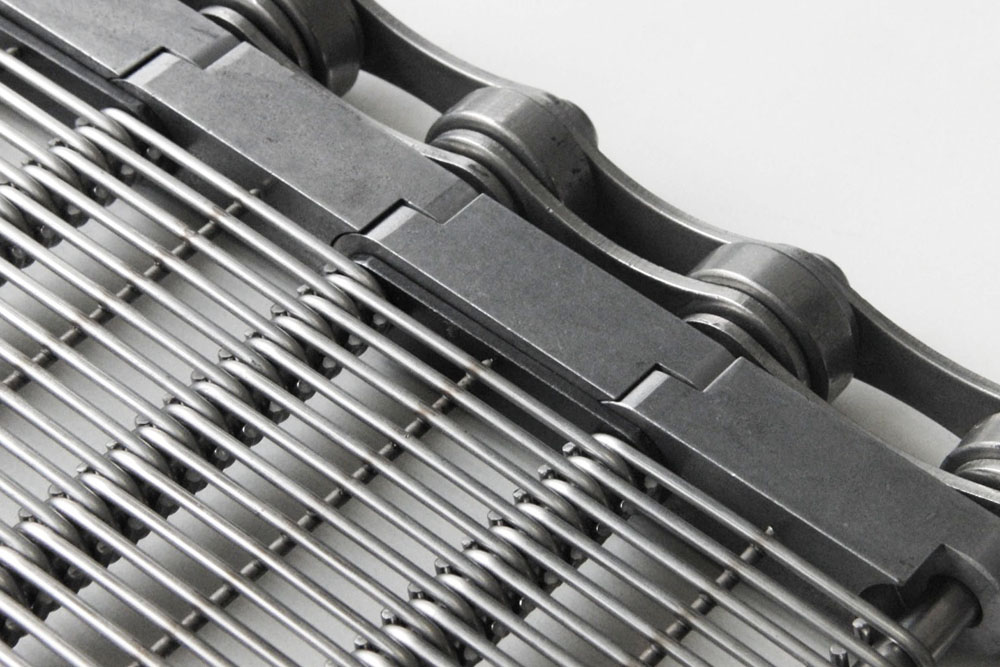

Conveyor belt prices depend on factors like material type, design, size, and intended application. For example, stainless steel conveyor belts, known for their durability and corrosion resistance, generally cost more than belts made from other materials.

Material and Build Quality Matter

The material used in conveyor belts plays a crucial role in determining the cost. Stainless steel belts, especially food-grade SS304 or SS316, are more expensive due to their heat, corrosion, and wear resistance. However, they offer long-term savings by requiring less maintenance.

Design and Application

Have you considered how a belt’s design impacts its price? Close wire mesh belts are ideal for delicate or small products and may cost more due to their intricate design. On the other hand, belts with large openings, used for cooling and drying, are typically more affordable and easier to clean.

Size and Customization

Does your application require custom dimensions? Conveyor belts with unique specifications or special features often have higher prices. The customization adds to the cost but ensures the belt meets precise operational needs.

Understanding conveyor belt prices means evaluating the material, design, application, and customization requirements. Investing in high-quality stainless steel belts may seem costly initially but provides durability, efficiency, and hygiene in the long run. Choose wisely to maximize value and performance for your specific needs!

Request a quote